Epoxy vs Polyaspartic Garage Floors | Roseville, CA (Pros & Cons)

If you’re comparing epoxy vs polyaspartic garage floors in Roseville, CA, you’re not alone. Many homeowners reach this point after hearing conflicting advice, seeing wide price differences, or receiving estimates that recommend completely different systems.

Some contractors push epoxy. Others promote polyaspartic as the only solution. One-day installs sound appealing, while warnings about moisture and long-term failure create hesitation. The reality is that both epoxy and polyaspartic garage floor coatings have strengths and limitations — and understanding how each one works is the key to making the right decision.

This guide explains the real pros and cons of epoxy vs polyaspartic garage floors, how each performs in Roseville-area garages, and why the overall coating system matters more than the product name alone.

If you’re researching garage floor coatings and have questions about durability, moisture, or installation, you may also find our garage floor coatings FAQ helpful.

Why the Epoxy vs Polyaspartic Decision Matters

Garage floor conditions in Roseville and surrounding Northern California communities are different from many other regions. Even when concrete looks dry, many garage slabs experience moisture vapor transmission from below, which is one of the most common causes of coating failure.

At the same time, homeowners want a garage floor that:

Looks clean and finished

Holds up to vehicles, chemicals, and daily use

Resists yellowing or fading over time

Can be installed efficiently with minimal disruption

Understanding where epoxy performs best, where polyaspartic excels, and how they work together helps homeowners avoid premature failure and choose a system that lasts.

In the sections below, we’ll break down:

What epoxy garage floor coatings do well

Where polyaspartic coatings perform best

How cost, moisture, and installation affect performance

Why many professional systems combine both materials

If you’re deciding between epoxy and polyaspartic garage floors in Roseville, this comparison will help you make a confident, informed decision before requesting estimates.

What Is an Epoxy Garage Floor Coating?

Epoxy garage floor coatings are widely used as a base layer in professional garage floor systems because of their strong adhesion to concrete and ability to handle moisture coming up through the slab.

Epoxy is a two-part coating made by combining resin and hardener. When applied to properly prepared concrete, it chemically bonds to the surface, creating a dense, durable foundation that other layers can build on.

In Roseville and surrounding Northern California communities, epoxy performs especially well because it:

Bonds deeply into mechanically ground concrete

Helps resist moisture vapor transmission from below

Creates a stable base for decorative flake systems

Provides excellent coverage and hide in a single coat

This makes epoxy an ideal base coat for garages where concrete condition and moisture levels vary — which is common in this region.

What Epoxy Does Well

When installed correctly, epoxy garage floor coatings offer several important advantages:

Excellent adhesion to concrete

Epoxy penetrates open concrete pores created by diamond grinding, forming a strong mechanical bond.Moisture resistance

Professional epoxy systems can help manage moisture vapor emissions that would otherwise cause coatings to bubble or peel.Uniform appearance

Epoxy provides consistent color and coverage, which is why it’s commonly used under full decorative flake broadcasts.Structural stability

As a base layer, epoxy creates a solid platform for topcoats like polyaspartic to perform at their best.

Limitations of Epoxy When Used Alone

While epoxy is an excellent base, epoxy-only garage floor systems do have limitations when used without a protective topcoat:

Slower cure times compared to polyaspartic materials

Limited UV resistance, which can lead to yellowing over time

Less abrasion resistance without a clear protective layer

For these reasons, epoxy performs best as part of a multi-layer system, rather than as a standalone, single-coat application.

What Is a Polyaspartic Garage Floor Coating?

Polyaspartic garage floor coatings are advanced, fast-curing materials commonly used as a protective top coat in professional garage floor systems. They are known for their durability, UV stability, and ability to return garages to service quickly.

Polyaspartic is a two-component coating that cures much faster than traditional epoxy. When applied over a properly prepared epoxy base, it forms a tough, chemical-resistant surface designed to withstand daily garage use.

In Roseville and surrounding Northern California communities, polyaspartic coatings are especially valued because they:

Cure quickly, even in cooler or variable temperatures

Resist yellowing or fading from sunlight exposure

Provide excellent abrasion and chemical resistance

Allow garages to be used again within 24 hours in many cases

These qualities make polyaspartic an ideal clear top coat for garages where appearance, durability, and minimal downtime matter.

What Polyaspartic Does Well

When used correctly, polyaspartic garage floor coatings offer several key advantages:

Fast cure times

Polyaspartic materials cure much faster than epoxy, allowing for shorter installation timelines and quicker return to service.UV stability

Unlike epoxy, polyaspartic coatings are naturally UV-resistant, helping prevent yellowing or discoloration over time — especially in garages with windows or frequent door exposure.High abrasion and chemical resistance

Polyaspartic top coats protect against tire wear, road salts, oil, and common household chemicals.Smooth, high-gloss finish

When applied over a full decorative flake broadcast, polyaspartic creates a seamless, professional-looking surface that’s easy to clean and maintain.

Limitations of Polyaspartic When Used Alone

While polyaspartic coatings offer excellent surface protection, polyaspartic-only systems have important limitations when used without an epoxy base:

Limited moisture protection

Polyaspartic does not penetrate concrete as deeply as epoxy and offers less resistance to moisture vapor transmission from below the slab.Reduced bonding strength on concrete

Without an epoxy base, polyaspartic relies more on surface adhesion rather than deep mechanical bonding.Less forgiveness during installation

Fast cure times leave little room for error, which can impact adhesion if surface preparation is rushed or incomplete.

Because of these limitations, polyaspartic performs best as a top coat, not as a standalone solution — especially in garages where moisture vapor is present, which is common in the Roseville area.

Why a Hybrid Epoxy + Polyaspartic System Performs Best

While epoxy and polyaspartic coatings each have strengths on their own, the most durable and reliable garage floor systems use both materials together in a hybrid installation.

A hybrid epoxy + polyaspartic system is designed to take advantage of what each coating does best — rather than relying on a single product to do everything.

In professional garage floor installations, the system typically includes:

An epoxy base coat that bonds deeply to the concrete and manages moisture

A full decorative flake broadcast for texture, thickness, and coverage

A polyaspartic clear top coat that seals and protects the surface

This layered approach creates a coating system that is stronger, longer-lasting, and better suited for real-world garage conditions — especially in Roseville and surrounding Northern California communities.

How the Hybrid System Works

Epoxy Base Coat (Foundation Layer)

The epoxy base coat is applied directly to mechanically ground concrete. Its low viscosity allows it to penetrate open concrete pores, creating a strong mechanical bond and helping manage moisture vapor transmission from below the slab.

This base layer:

Provides excellent adhesion to concrete

Helps reduce the risk of bubbling or peeling caused by moisture

Creates a stable surface for decorative flakes and top coats

Decorative Flake Broadcast (Build & Texture)

A full broadcast of decorative flakes is applied into the wet epoxy base coat. This adds thickness, texture, slip resistance, and uniform coverage, while also locking the system together.

Polyaspartic Clear Top Coat (Protection Layer)

Once the epoxy and flake layers have cured, a polyaspartic clear coat is applied to seal the system. This top coat provides:

UV resistance to prevent yellowing

High abrasion and chemical resistance

A smooth, easy-to-clean surface

Faster return to service compared to epoxy alone

Why Hybrid Systems Outperform Single-Layer Coatings

Compared to epoxy-only or polyaspartic-only systems, hybrid systems offer several long-term advantages:

Better moisture tolerance than polyaspartic-only systems

Better UV stability than epoxy-only systems

Improved adhesion and longevity compared to single-coat applications

Consistent appearance and performance across the entire garage

This is why professionally installed hybrid systems routinely last 15 years or more when properly prepared and installed — even in garages with moisture challenges or heavy daily use.

Why System Design Matters More Than Product Names

Many garage floor failures occur not because of the material itself, but because the system design was wrong for the garage conditions.

A properly designed hybrid epoxy + polyaspartic system accounts for:

Concrete condition

Moisture vapor levels

Climate and temperature during installation

Long-term wear from vehicles, tools, and foot traffic

By combining epoxy and polyaspartic in the right order and thickness, homeowners get a garage floor that performs as well as it looks — without cutting corners that lead to premature failure.

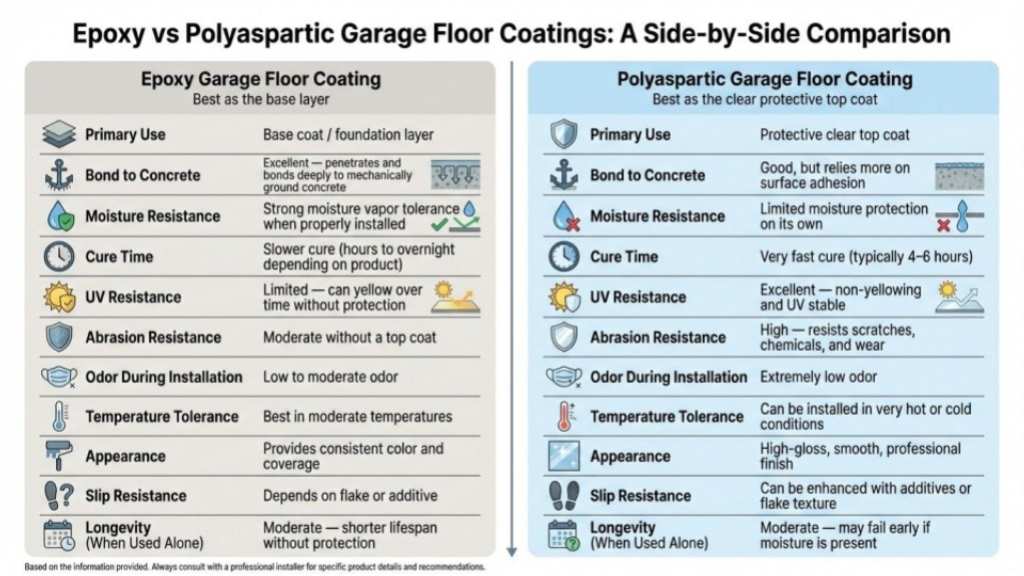

Epoxy vs polyaspartic garage floor coatings — side-by-side comparison for Roseville homeowners

Epoxy vs Polyaspartic Garage Floors | Roseville, Ca: Which Is Better?

When comparing epoxy vs polyaspartic garage floor coatings in Roseville, CA, the “better” option depends less on the product name and more on how Roseville-area garages actually perform over time.

Many garage slabs in Roseville and surrounding Placer County communities experience moisture vapor transmission from below — even when the concrete surface appears dry. This moisture is one of the most common causes of garage floor coating failure, leading to bubbling, peeling, or delamination when the wrong system is used.

At the same time, homeowners want a garage floor that:

Looks clean and finished year-round

Holds up to vehicles, chemicals, and daily use

Resists yellowing or fading from sunlight

Can be installed efficiently without cutting corners

Why Epoxy Alone Isn’t Always Enough

Epoxy garage floor coatings perform extremely well as a base layer, especially in Roseville where concrete conditions and moisture levels can vary. Epoxy bonds deeply into mechanically ground concrete and helps manage moisture vapor coming up through the slab.

However, epoxy used on its own has limitations. Without a protective topcoat, epoxy can yellow over time, wear faster under traffic, and take longer to fully cure.

Why Polyaspartic Alone Can Be Risky

Polyaspartic coatings are often marketed as a complete “one-day” solution — and while they cure quickly and resist UV damage, polyaspartic on its own offers limited moisture protection.

In garages with moisture vapor issues, polyaspartic-only systems can fail prematurely if moisture mitigation isn’t addressed at the base layer.

The Reality for Roseville Garages

For most Roseville homes, the best-performing garage floors are not epoxy-only or polyaspartic-only systems.

They are hybrid systems that use epoxy where it performs best — bonded directly to concrete — and polyaspartic where it excels — as a durable, UV-stable protective topcoat.

This approach accounts for local concrete conditions, seasonal temperature changes, and long-term durability, rather than relying on speed or marketing claims alone.

In the next section, we’ll explain why combining epoxy and polyaspartic into a single system delivers the most reliable long-term results for Roseville garages.

Why We Use a Hybrid Epoxy + Polyaspartic System

At TRICO PAINTING, we don’t believe in one-size-fits-all garage floor coatings. After working on garages throughout Roseville and surrounding Northern California communities, we’ve found that the most reliable long-term results come from a hybrid epoxy + polyaspartic garage floor coating system.

This hybrid epoxy + polyaspartic approach is the foundation of our epoxy + polyaspartic garage floor coating system designed for long-term performance in Roseville garages.

The epoxy and polyaspartic materials we use are manufactured by E2U, a professional-grade coatings supplier known for high-performance garage floor systems.

Epoxy Where It Matters Most: At the Concrete

We use a professional-grade epoxy base coat because epoxy excels at bonding directly to concrete. When applied over mechanically diamond-ground concrete, epoxy:

Penetrates deeply into the slab for superior adhesion

Helps manage moisture vapor transmission from below

Creates a stable, uniform base for decorative flake systems

Provides excellent coverage and hide in a single coat

In Roseville-area garages, where moisture conditions can vary widely from home to home, epoxy serves as the foundation that protects against premature coating failure.

Polyaspartic Where Protection Counts: On the Surface

Once the epoxy base and full decorative flake broadcast are complete, we finish the system with a polyaspartic clear topcoat. Polyaspartic is ideal as a top layer because it:

Cures quickly, allowing faster return to service

Resists UV exposure without yellowing

Offers excellent abrasion and chemical resistance

Maintains a smooth, professional, high-gloss finish

Performs reliably in both hot and cold installation conditions

This topcoat protects the epoxy and flake layers beneath it, extending the life of the entire system.

Why This System Outperforms Single-Product Solutions

Epoxy-only systems often wear faster or discolor without a protective topcoat.

Polyaspartic-only systems can struggle with moisture-related failures when installed directly over concrete.

By combining epoxy and polyaspartic into a single, properly layered system, we’re able to:

Address moisture concerns at the slab level

Deliver a durable, long-lasting finish at the surface

Avoid shortcuts that lead to bubbling, peeling, or delamination

Create a garage floor that looks great and performs for years

This hybrid approach isn’t about speed or marketing claims — it’s about building garage floors that hold up in real Roseville homes.

In the next section, we’ll break down how epoxy and polyaspartic compare side-by-side, so you can clearly see how each material performs on its own — and why they work best together.

How Cost Differs Between Epoxy, Polyaspartic, and Hybrid Garage Floor Systems

One of the most common questions homeowners ask when comparing epoxy vs polyaspartic garage floors in Roseville is how much each option costs — and why estimates can vary so widely.

Garage floor coating prices are influenced by more than just square footage. In Roseville-area homes, cost differences typically come down to:

Concrete condition and preparation requirements

Moisture vapor levels in the slab

The type of coating system being installed

Whether decorative flakes and protective topcoats are included

Understanding these factors makes it easier to compare estimates accurately and avoid systems that look affordable upfront but fail prematurely.

Epoxy-Only Systems: Lower Upfront Cost, Fewer Layers

Epoxy-only garage floor systems generally have the lowest upfront cost. These installations rely on epoxy as both the bonding layer and the finished surface.

While epoxy bonds well to concrete, epoxy-only systems often:

Lack UV stability without a protective topcoat

Wear faster under vehicle traffic

Require longer cure times

Offer less protection against long-term moisture issues

For garages with minimal moisture and light use, epoxy-only systems may be suitable. However, in many Roseville garages, moisture and daily use make epoxy-only systems more prone to long-term wear or failure.

Polyaspartic-Only Systems: Faster Install, Higher Risk Without Proper Prep

Polyaspartic-only systems are often marketed as one-day garage floor coatings, which can make them appealing to homeowners looking for quick turnaround.

These systems typically come with a higher upfront cost than epoxy-only installations, but performance depends heavily on:

Extremely dry concrete conditions

Aggressive surface preparation

Limited margin for installation error

Without proper moisture mitigation, polyaspartic-only systems can be less forgiving in garages where moisture vapor is present — which is common in the Roseville area.

Hybrid Epoxy + Polyaspartic Systems: Better Value Over Time

Hybrid epoxy and polyaspartic garage floor systems typically fall into a mid-to-upper price range, reflecting the added materials, preparation, and performance benefits involved.

These systems combine:

An epoxy base coat to bond to concrete and manage moisture

A full decorative flake broadcast for thickness and durability

A polyaspartic clear topcoat for UV stability, chemical resistance, and wear protection

While the upfront cost of a hybrid system may be higher than a basic epoxy-only installation, it often delivers better long-term value by reducing the likelihood of premature failure, repairs, or replacement.

Why Garage Floor Coating Prices Vary So Much in Roseville

If you’ve received multiple quotes for garage floor coatings in Roseville, large price differences usually reflect:

The level of surface preparation included

Whether moisture testing is performed

The quality and number of coating layers applied

The experience of the installer

Comparing estimates without understanding what’s included can lead to disappointing results.

👉 For a more detailed breakdown of local pricing ranges and what affects cost, see our guide on garage floor coating cost in Roseville, CA.

Common Mistakes Homeowners Make When Choosing a Garage Floor Coating

Most garage floor coating failures don’t happen because a homeowner chose the “wrong” product — they happen because of decisions made during the selection process. Understanding these common mistakes can help you avoid premature failure and disappointing results.

Choosing Based on Speed Instead of System Design

Fast, one-day installations can sound appealing, but speed alone doesn’t determine long-term performance. Some systems prioritize rapid cure times over proper surface preparation or moisture evaluation.

A garage floor that installs quickly but fails in a few years is rarely a good value.

Skipping Moisture Testing

Concrete can contain moisture even when the surface looks completely dry. Without testing for moisture vapor emissions, coatings may be applied to slabs that are not suitable for certain systems.

Moisture-related issues are one of the most common causes of bubbling, peeling, and delamination in garage floors — especially in Northern California homes.

Comparing Quotes Without Comparing What’s Included

Not all garage floor coating estimates include the same steps or materials. Price differences often reflect:

The level of surface preparation performed

Whether moisture mitigation is included

The number of coating layers applied

Whether decorative flakes and protective topcoats are part of the system

Comparing estimates based only on price can lead to unexpected compromises in performance.

Assuming All Coatings Perform the Same

Epoxy, polyaspartic, and hybrid systems each serve different purposes. Treating them as interchangeable products can result in choosing a system that doesn’t match the garage’s concrete condition or long-term use.

Understanding how each material is intended to be used helps prevent mismatched expectations.

Choosing Price Over Long-Term Performance

Lower-cost systems may appear attractive upfront, but they often involve thinner coatings, reduced preparation, or limited moisture protection. Over time, this can lead to repairs or replacement that cost more than installing the right system from the start.

A properly designed garage floor coating system should be evaluated based on durability, performance, and longevity, not just initial price.

How to Avoid These Mistakes

The best way to avoid these issues is to work with a contractor who:

Evaluates the concrete slab before recommending a system

Explains how moisture and preparation are handled

Clearly outlines what’s included in the installation

Recommends solutions based on performance, not shortcuts

Get a Professional Garage Floor Evaluation in Roseville, CA

If you’re comparing epoxy vs polyaspartic garage floors, the best next step isn’t guessing — it’s getting a professional evaluation of your concrete and garage conditions.

At TRICO PAINTING, we take the time to evaluate each garage individually, including:

Concrete condition and surface preparation needs

Moisture levels in the slab

How your garage is used day to day

Which coating system will perform best long-term

This allows us to recommend a garage floor coating system based on performance, durability, and value — not marketing claims or shortcuts.

If you’re located in Roseville or the surrounding area and considering a garage floor coating, we’re happy to answer questions, explain your options, and provide a clear, no-pressure estimate.

📞 Call TRICO PAINTING today to schedule your garage floor evaluation

📍 Serving Roseville, Rocklin, Granite Bay, Folsom, and nearby communities

Or call us at (916) 550-9648